Cost-saving automatic helium recovery & purification system - LDetek LDRPS

)

Automated system for recovering and purifying gases used in gas chromatography (GC)

The on-going global helium shortage has resulted in a scarcity of helium supply and high operational costs. To reduce operational expenses, recycling and purifying helium gas has become crucial. Industry leaders are implementing new measures to preserve the production and use of helium in their industrial sites.

The LDetek LDRPS is a cost-effective solution for industrial sites that use helium. It can save up to 85% on the cost of using helium, providing a quick return on investment and security during a shortage.

Additionally, this system reduces the risk associated with bottle rotation, which is common with standard gas chromatography systems.

LDetek LDRPS is an automated gas recovery and purification system explicitly designed to recycle the helium carrier gas used by gas chromatographs.

It is able to collect waste carrier gas from any gas chromatograph exhaust without causing pressure fluctuations or build-up. It builds up pressure to the required level for the GC inlets, stores excess gas in a reservoir, purifies any grade waste gas up to 99.999999% using a multi-step heated purifier system, and measures trace impurities (ppb/ppm) of nitrogen and moisture using a micro plasma detector to validate the purity of the recycled carrier gas before returning it to the gas chromatograph.

LDetek LDRPS allows continuous recycling, repurifying, and repressurizing of the exact source of helium or other gases in a continuous loop. It considerably reduces the operating cost of a gas chromatography system or any other process.

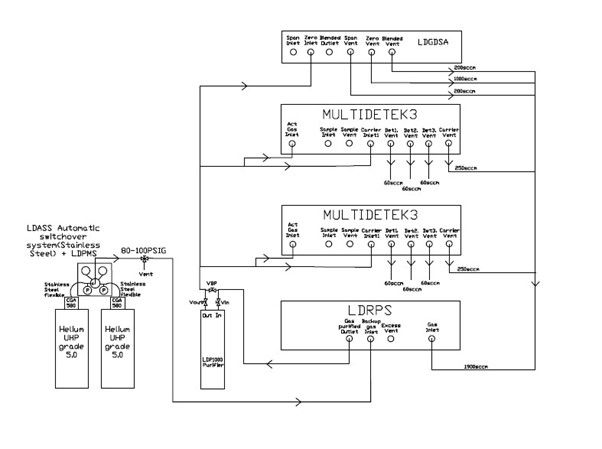

The LDetek LDRPS was tested on an industrial gas supplier site using 2 MultiDetek3 gas chromatograph units combined with 1 LDGDSA dilution system, and below are our findings in terms of helium consumption/saving:

| Without LDPRS | With LDPRS |

|

8,000,000 / 2260 = 3,540 minutes 60 minutes x 24 hrs = 1440 minutes per day 8,888 / 1440 = about 2.5 days with one bottle of Helium to feed the system Annual consumption: 146 bottles Estimated price for Helium grade 5.0: 600USD Estimated annual price: 87,600 USD* *The price depends on the helium price per bottle and the frequency of use of the LDGDSA dilution system. |

8,000,000 / 360 = 22,222 minutes 60 minutes x 24 hrs = 1440 minutes per day 22,222 / 1440 = about 15 days with one bottle of Helium to feed the system Annual consumption: 24 bottles Estimated price for Helium grade 5.0: 600USD Estimated annual price: 14,400 USD* |

Approximative 84% annual saving using LDPRS: 73,200.0 USD

Product Features

- 5..55 °C operating temperature range

- 0...100 °C sample gas temperature

- 0…2 lpm recycling gas flow rate capacity

- 0…20 psig (sub-atmospheric available) gas collecting pressure range

- 1/4'' Swagelok compression or VCR inlet and outlet fittings

How does it work?

A built-in heated dual-getters purifier purifies the recycled gas. The quality of the purified gas produced is then measured by an integrated plasma emission detector. Combining the specific flexible membrane with a network of position and pressure sensors makes the system intelligent and fully automatic. The system has been designed with state-of-the-art components to ensure its high purity and that it is leak-free.

Visit our product page to learn more.

The LDetek LDRPS is also compatible with any other type of gas source that must be recycled.

Contact Us to discuss your application.

About Process Sensing Technologies

Process Sensing Technologies (PST) provides an unmatched suite of instruments, analyzers and sensors for precision measurements and monitoring in highly demanding end markets. These range from pharmaceutical/ life sciences, speciality gases, semiconductors, O&G, petrochemicals and power to gas detection, food and beverage and building automation.

PST brings together well-established brands, each of which are trusted for the precision and reliability of their products, strong innovation and singular focus on customer service. With a history of development and innovation starting in 1965 and continuing to the present day, we look forward to many more milestones to come.

For marketing enquiries, please contact:

Katie Golsby, Senior Technical Editor | PST Michell | Dew Point Division Tel: +44(0)1353 658 000

Email: katie.golsby@processsensing.com

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)